Add Hot Ethanol Again Dropwise Until the Cloudiness Disappears Why Does the Cloudiness Disappear

Expt. 1, Part B. Recrystallization and Melting Indicate Determinations.

Introduction

1. Recrystallization

Products from an organic reaction are seldom obtained in a pure state directly from the reaction mixture. If the production is a solid, it may be purified by recrystallization from a suitable solvent. The process of crystallization depends on the fact that most organic compounds are more soluble in hot solvents than in cold, and that the impurities nowadays will take different solubilities from the desired compounds. The procedure involves:

(a) dissolving the impure material in a minimum amount of hot solvent (if too much solvent is added, the excess tin can be boiled off),

(b) filtering the hot solution at its boiling point to remove insoluble impurities when present (this filtration is required merely when insoluble impurities are observed),

(c) allowing the solution to absurd and deposit crystals of the compound,

(d) filtering the crystals from the solution (called the mother liquor,

(e) washing the crystals with a little cold solvent to remove the mother liquor, and

(f) drying the crystals to remove the last traces of solvent.

In this experiment, recrystallization from a unmarried solvent (water) volition be illustrated.

Properties of an Ideal Recrystallizing Solvent

If recrystallization is to be effective, the solvent must exist properly selected. A adept recrystallization solvent should:

(a) dissolve a moderate quantity of the substance to be purified at an elevated temperature, but merely a small-scale quantity at low temperatures

(b) not react with the substances to be purified

(c) dissolve impurities readily at a low temperature or not deliquesce them at all

(d) be readily removable from the purified product.

This last requirement unremarkably means that the solvent must accept a relatively low boiling point and evaporate readily.

How to Detect a Good Recrystallizing Solvent

Let us presume that you have an unknown compound and you lot want to purify it by crystallization. First, determine its solubility properties in uncomplicated available solvents.

It is usual to try water (seldom successful), methanol, ethanol, acetic acid, petroleum ether (available in several boiling ranges) and, less commonly, ether, chloroform, ethyl acetate, acetonitrile, benzene and dimethylformamide. Add together virtually 20 mg of fabric to ane ml of cold solvent. Shake up to 3 min to assistance dissolution. If insoluble, warm the solvent to humid. Note the solubility properties in each solvent (common cold and hot). Ideally your material should be insoluble in cold solvent and soluble in hot solvent; if yous find a solvent with these properties you can cease here every bit this will probably exist a suitable solvent for recrystallization.

If no single solvent is found suitable, and then a mixed solvent recrystallization is in order. For this yous crave 2 miscible solvents. For mixed solvent recrystallization your material should exist relatively soluble in one solvent and relatively insoluble in some other solvent.

For example, a substance which is very soluble in alcohol and virtually insoluble in water may crystallize well from a mixture. The correct process is to dissolve the solid in the minimum amount of boiling booze and add together warm water dropwise. Each drop will produce a cloudiness which at outset clears on mixing. When the warmed solution just fails to clear on shaking, a few drops of alcohol are added, the mixture is re-heated and prepare aside for crystallization. Any insoluble impurities are all-time removed by filtering the hot booze solution before adding water. All these organic solvents have their individual hazards and contact with both liquid and vapour should be avoided. Special attending is drawn to benzene which is now recognized as a cumulative toxicant affecting the blood. Even low concentrations of benzene vapour should therefore exist avoided.

Some Further Points on Recrystallization

Often, information is available apropos solvents suitable for recrystallizing a item chemical compound. If information technology is not, several solvents may be tested. This is done by placing a minor amount of the substance to exist purified in each of several test tubes and calculation a modest amount of a different solvent to each. Solubility is noted in the cold solvent and at its humid point; one also observes whether abundant, well-formed crystals are produced on cooling the hot solutions.

To obtain a good recovery of purified material, the apply of unnecessarily big volumes of solvent must be avoided. The amount of pure material lost by retention in the mother liquor will be minimized if the substance is dissolved in the smallest amount of hot solvent. In practice, 3-5% more than the minimum is used and then that the hot solution will not be quite saturated. This helps prevent the separation of crystals and clogging of the filter newspaper during filtration of the hot solution.

Traces of coloured matter or resinous impurities may sometimes exist removed with selective adsorbents, such as finely divided charcoal (Norit, Darco). A small amount of decolourizing charcoal is added to the hot solution before information technology is filtered. Excess of decolourizing agent should be avoided, still, because information technology may also adsorb observable amounts of the substance being purified.

Some substances readily form supersaturated solutions, and crystallization may not occur spontaneously when the hot solution is cooled. In such situations, crystallization can sometimes be initiated by scratching the walls of the vessel with a stirring rod, beneath the surface of the solution. The best method to induce crystallization is to "seed" the cold solution with one or 2 pure crystals of the substance being purified. Although some compounds crystallize readily, others may carve up from solution as oils, and may require hours or even days before they crystallize.

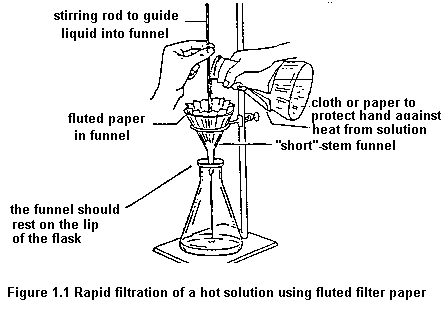

Apparatus for Vacuum Filtration

To remove insoluble impurities and decolourizing charcoal, hot solutions must be filtered speedily. Otherwise, the solution cools and crystals deposit prematurely. Rapid filtration may be achieved by using fluted filter paper (paper folded with many pleats to give a big surface, Figure 1.i) or, more commonly, past using a vacuum to increase the filtration charge per unit. The appliance for vacuum filtration is shown in Effigy one.2. A Buchner or a Hirsch funnel is fitted to a filter flask with a neoprene adaptor. A disk of filter paper of a size adequate just to cover all the holes in the funnel is placed in the funnel and moistened with some of the solvent used in the recrystallization. The filter flask is then joined to the aspirator and vacuum is applied. When the filter paper is drawn down tightly to the funnel, filtration of the solution is begun. During filtration, information technology is of import not to plough off the aspirator or to subtract the aspirator flow rate as this may crusade "suck dorsum" of tap h2o into the filtration flask. For this reason, it is besides important to break vacuum at either hose connection before turning the aspirator off.

Melting Point Conclusion

A melting point can be used to identify a substance and to get an indication of its purity. The melting bespeak (or freezing bespeak) of a solid is the temperature at which the solid exists in equilibrium with its liquid state under an external pressure of one temper. More than precisely, it is the temperature at which the vapor force per unit area of the solid phase becomes equal to the vapor pressure level of the liquid phase. Experimentally, it is extremely hard to establish the verbal temperature at which this equilibrium is established; therefore, the temperature range over which liquid and solid are establish to coexist is called the melting point. For example, a solid may be reported to have a `melting bespeak' of 100-101oC; this means that, on heating slowly, the get-go droplet of liquid was observed at 100oC and the concluding crystal of solid disappeared at 101oC.

Both the melting point range (the interval between the beginning of liquefaction and complete liquefaction) and the temperature of complete liquefaction are valuable indicators of the purity of the solid chemical compound. A pure crystalline organic compound usually possesses a sharp melting signal and it melts completely over a narrow temperature range of not more than than 0.5-1.0oC, provided practiced technique is followed. The presence of even minor amounts of impurities commonly produces a depression of the temperature at which melting is complete and commonly produces a marked increment in the width of the melting point range. For example, if a sharp-melting unknown substance X is suspected of being identical with some known substance A, the two should accept the same melting points. If A is reported to have a melting point rather different from that observed for X, the two substances may be identical (the pocket-size differences being due to variations in technique of determining the melting points). Whether they are indeed identical tin can often be deduced speedily if a sample of A is available, by determining a mixture melting point. A mixture of X and A should take the aforementioned melting bespeak as that of either substance alone, provided the ii substances are identical.

If Ten and A are not the same substance (even though they separately have the same melting point), then a mixture of the two volition usually show a lower melting point and a broader melting betoken range than either substance lonely. This is considering each substance acts as an impurity in the other. Miscible or partially miscible impurities, even when present in small amounts, commonly lower the melting point and broaden its range.

A wide melting betoken range usually indicates that a substance is impure, but it may also result from the fact that the pure substance undergoes some decomposition prior to reaching its melting indicate. In some cases, the textile undergoes a slight liquefaction and wrinkle at a temperature below the truthful melting bespeak; in others, the textile may decompose and discolour and so badly that a definite melting bespeak cannot exist observed.

Theory of Melting Betoken Depression

The theory underlying the solid/liquid change of state is based primarily on the miracle of vapor pressure level. Both liquid and solid forms of a compound exert vapor pressure; vapor pressure increases with increasing temperature but that of the solid increases more than rapidly than that of the liquid. At the melting signal, the vapour pressures of the solid and liquid phases are equal. A soluble impurity lowers the partial vapour pressure of the pure substance in the melt and thus lowers the temperature necessary for melting. The temperature dependence of the vapor pressure level of a pure compound, A, is concisely summarized by a typical phase diagram, Figure 1.3.

2 points in Figure ane.4 may exist identified: TB, the normal boiling indicate, the temperature at which the vapor force per unit area of the liquid equals atmospheric pressure, and TM, the melting (or freezing) signal, the point on the solid liquid line equal to the atmospheric pressure.

The "true" melting point is the temperature at which all three phases (vapor, liquid, solid) coexist -- i.e., the "escaping tendencies" from whatsoever 1 phase to another are equal. The full pressure of the system is, then, the vapor pressure of the compound at that temperature.

"Ordinary" melting points, however, are determined at atmospheric pressure and differ slightly from true melting points. Melting points are not markedly affected past modest changes in external pressure because the solid/liquid phase transition does not involve a significant change in molal volume. Withal, at very high pressure, startling differences may be observed: east.one thousand., at 33,880 atm., the melting point of water is 166.vioC instead of 0oC.

The outcome of a small amount of an impurity, B, on the melting point of A may exist evaluated by the following considerations. Suppose that a small amount of B were introduced into the equilibrium mixture of pure, solid and liquid A and that B immediately dissolves in liquid A but non in solid A, which it cannot quot;penetrate".

According to Dalton's Law the vapor pressure of a liquid solution is the sum of the partial pressures of the components. Therefore, the presence of this dissolved impurity volition lower the partial vapor pressure due to liquid A throughout the whole temperature range as shown by the `dashed' curve in Figure one.3. It is articulate and then that the vapor force per unit area of solid A will become equal to that of liquid A in solution at temperature TM' which is below the melting point TOne thousand of pure A -- i.e. the effect of the impurity is to depress the melting signal of the pure compound.

Farther additions of small quantities of the impurity will produce respective lowerings in the partial vapor pressure of A in the liquid melt and hence too, in the melting point of compound A. Finally, however, a limiting point is reached at which the impurity concentration is just sufficient to `saturate' liquid A; any boosted impurity does not dissolve and cannot farther depress the melting point. This bespeak is known as the Eutectic Indicate and the limiting temperature is called the Eutectic Temperature and the composition of the cook, the Eutectic Composition. Alternatively, the eutectic temperature can exist described as the temperature below which a mixture of A and B cannot be as a liquid; or, the temperature at which A and B can co-crystallize from the liquid cook.

Eutectic Point

The nature of the eutectic betoken and, more than importantly, its influence on the observed melting point range are more effectively illustrated by a generalized, equilibrium temperature versus limerick diagram, Figure i.4. In this diagram, point a represents the melting point of pure compound A; the bend aE represents the temperatures at which solutions of different concentrations of B (the impurity) in A are in equilibrium with solid A -- i.due east., for any particular concentration, the curve indicates the temperature at which the last trace of A will melt when the solid mixture is heated or the temperature at which the first trace of A will crystallize if the liquid mixture is cooled. Similarly, point b represents the melting point of pure B and the curve be represents the temperatures at which solutions of different concentration of A (the impurity) in B are in equilibrium with solid B. At the eutectic point, E, both solid components can be in equilibrium with a liquid solution of that particular composition. One might consider the liquid at the eutectic point to be a saturated solution of either solute A in solvent B or, solute B in solvent A. Cooling of the eutectic liquid volition bring near crystallization (freezing) of both A and B at a constant temperature, the eutectic temperature and at a constant limerick, the eutectic limerick.

To evaluate the effect of an impurity on the melting point range, consider the effect of heating a mixture of A (eighty%) with an amount of impurity, B (xx%), less than the eutectic concentration. To establish the range we must know where the mixture will brainstorm to melt. When estrus is applied, the temperature of the solid mixture will rise; no changes in the physical state of the system will occur until the eutectic temperature is reached. At that temperature, bold that the heating tin exist controlled sufficiently that equilibrium atmospheric condition are ensured, advisable numbers of molecules of A and B already in contact at the crystal/crystal interfaces will `cook' to form a liquid stage of eutectic composition (in this case 60/40). Every bit heating is connected more A and B will melt at the eutectic composition and the eutetic temperature, until all of B (the minor component) is entirely melted leaving only solid A in equilibrium with the eutectic liquid. On further heating, the remaining solid A will begin to cook. This, nonetheless, will heighten the pct of A in the liquid above the eutectic composition. Since the partial vapor force per unit area due to A in the liquid is thereby increased, the temperature (melting point.) at which solid A is in equilibrium with the liquid must too rising. In this fashion, melting will proceed, at progressively increasing temperatures (represented past the curve EF in Figure 1.4) until the last trace of solid A becomes liquid at temperature F. Hence, if perfect equilibrium conditions were maintained, the melting point range for such a mixture would be from East, the eutectic temperature, to F.

Similarly, if nosotros were to consider a solid mixture with a composition to the correct of point E in Figure 1.iv, we would speak of a compound B with impurity A and the ascent temperature during the melting procedure would follow curves E D or Due east G.

In theory, then, for any solid compound containing a relatively small amount of impurity, melting will begin at the eutectic temperature and be complete at some temperature lower than the melting point of the pure compound. Moreover, if the concentration of the impurity were increased, the upper limit of the melting would be lowered and therefore the melting range decreased.

In practice, however, equilibrium conditions are almost never achieved and, moreover, it is extremely hard to detect the initial melting or eutectic condition. If only a very small amount of impurity is present (which is most frequently the case) the temperature may rising several degrees above the eutectic temperature before sufficient liquid phase accumulates to be visible to the human eye. Nevertheless, the temperature at which the last crystal disappears can be determined quite accurately.

Therefore, every bit actually observed, a well-nigh pure solid compound tends to bear witness a narrow melting range with an upper limit about the true melting betoken whereas a rather impure compound usually shows a broader melting range with the maximum temperature considerably below the true melting point.

It is clear from further consideration of Figure 1.iv that the effect of an impurity is not straight dependent on its own melting indicate. Thus, for example, a solid impurity whose melting point is higher than that of the compound will yet depress the latter'due south melting point (at least in amounts less than that of the eutectic composition). Information technology should as well be noted that a sample whose limerick is exactly that of the eutectic mixture will exhibit a precipitous melting signal, melting completely at the eutectic temperature. Thus a eutectic mixture may sometimes exist mistaken for a pure chemical compound. Such infrequent occurrences may exist identified past calculation a small amount of either component (assuming ane knows what the components are) and observing that the melting point rises. Finally, the eutectic point is not limited to mixture compositions around 50/50 (sixty/xl in the arbitrary example shown in Figure i.four) but may in principle occur at any composition depending but on the specific backdrop of the detail components.

Full general Technique for Melting Point Determination>

To decide the melting bespeak of a crystalline substance, a pocket-sized amount of the finely powdered crystals is introduced into a thin-walled capillary tube; the latter is placed on an electrically heated "hot-stage" and heated. Ii temperatures are recorded, the temperature at which the substance begins to liquefy and that at which it becomes completely liquefied. The observed melting betoken range is the interval between these 2 temperatures.

A pure crystalline organic substance usually possesses a sharp melting point; that is, it melts completely over a very short temperature range, usually not more than 0.v-ane.0oC, provided good experimental technique is used. The melting bespeak range is influenced not only by the purity of the textile simply also past the size of the crystals, the amount of material, the density of its packing in the tube, and the rate of heating the hot stage. A finite time is required to transfer heat from the hot-stage both through the walls of the capillary tube and throughout the mass of the sample. If the hot-stage is heated too quickly, its temperature volition rise several degrees during the time lag required for the melting process to occur; this results in an observed range higher than the true one.

To obtain good results it is essential, in the vicinity of the melting point, to heat the melting point hot-stage slowly at a uniform charge per unit, about 2 degrees per minute. To minimize lag in the melting procedure and heat transfer, a modest corporeality of cloth, finely powdered and densely packed in a thin-walled capillary of modest diameter, should be used. The elevation of solid in the capillary tube should be just plenty to permit good observation of the behaviour on melting (about three-4 mm).

The behaviour of a material on melting should be observed and recorded carefully, as, for example: melts sharply at 89.0-89.fiveoC; or mp 131-133oC, with decomposition; or discolours at 65oC, melts slowly at 67-69oC.

The Melting Betoken Stage

Several types of appliance used to make up one's mind melting points are shown in Figure 1.5. Types A to C are older versions and use liquids every bit the heat transfer agents. In this laboratory you will employ apparatus D which comes in two versions: i for use with a capillary tube and the other for utilise with a microscope comprehend slide. You should use whatsoever version is bachelor to you in your labaratory room. Make sure that you lot apply a high temperature (250 or 360oC) thermometer!

Decision of Melting Points

Procedure: Fill up a melting point tube with the sample of involvement past thrusting the open end into the powder several times. In order to work the plug of solid material down to the sealed finish of the tube, vigorously tap the sealed end on the table or lightly draw a file across the tube held loosely in the hand. Echo the procedure until the tube contains a iii mm column of densely packed pulverization in the bottom. Identify the capillary in the melting point stage and turn on the ability and allow the hot-stage temperature to rise fairly chop-chop to within 15-xxoC below the expected melting point of the chemical compound. However, during the decision of the actual melting point range, the temperature should not ascent more rapidly than 2 or threeo per minute. Therefore, decrease the charge per unit of heating near 15o below the expected melting point. Detect and record the melting range.

[Note: frequently it is faster to prepare two capillaries, perform i rapid approximate of your melting point, and and then do a more conscientious ane using a ii-3oC temperature rise per minute nearly your "gauge".]

Questions

ane. What effects do impurities have on the melting point of an organic compound?

two. How could the identity of a chemical compound be established by melting point determination?

References:

Pasto and Johnson, Organic Structure Conclusion, pp. 57-65.

Adamson, Textbook of Physical Chemistry, pp. 395-396.

CRC Printing, Handbook of tables for Organic Chemical compound Identification.

04sep97; wjl

Source: https://chemistry.mcmaster.ca/~chem2o6/labmanual/expt1/exp1b-i.html

0 Response to "Add Hot Ethanol Again Dropwise Until the Cloudiness Disappears Why Does the Cloudiness Disappear"

Postar um comentário